High-pressure, filtered & standard models with full customization. ISO9001-certified supplier.

Looking to source custom handheld shower heads in bulk? JEKARE is an ISO 9001–certified OEM/ODM manufacturer offering one-stop solutions for sanitary-ware brands worldwide.

We provide full customization—materials (ABS, stainless steel, brass), dimensions, logos/private labels, packaging, and functional types (high-pressure, low-pressure, filtered). With advanced equipment and strict quality control, we turn your designs into market-ready handheld shower heads quickly and reliably.

All categories

Baths

Bidets

Washbasins

Faucets

Toilets

Uncategorized

Plumbing

1Pair

2Pair

3Pair

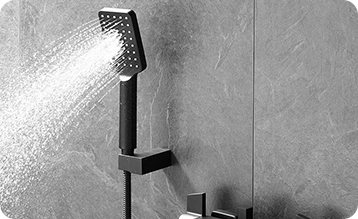

A handheld shower head is a detachable shower fixture mounted on a flexible hose, providing targeted, mobile water delivery for rinsing, cleaning, and accessible bathing. Custom handheld shower heads offer multiple spray patterns, water-saving and pressure-boosting options, and can include filtration or soft-touch ergonomics; they’re compatible with standard hoses and house plumbing and are widely used in residential, hospitality, and healthcare settings. OEM/ODM customization lets brands specify materials, finishes, flow rates, and packaging to meet market needs and performance requirements.

Handheld shower heads are available in several common designs to suit different installation requirements, spray preferences, and user needs. Understanding these types helps you choose the right handheld shower head for your bathroom application.

These feature a classic round or rectangular spray face with a flexible hose and wall-mounted holder. They offer balanced water coverage and are widely used in residential and hospitality bathrooms.

Designed with adjustable spray settings—such as rain, massage, mist, or combination modes—this type allows users to switch spray patterns for comfort, rinsing efficiency, or relaxation.

With a compact, lightweight profile, these models emphasize ease of handling and modern aesthetics. They are ideal for contemporary bathrooms and space-saving designs.

Engineered with optimized internal channels, these shower heads enhance spray force while maintaining controlled water flow, making them suitable for low-pressure water systems.

Integrated filtration elements help reduce chlorine and impurities, improving water quality and providing a gentler shower experience—commonly preferred in wellness-focused bathroom designs.

All handheld shower head types can be customized in materials, spray face design, finishes, and hose connections to meet specific functional and aesthetic requirements.

We engineer nozzles and internal flow channels using empirical testing to deliver consistent pressure, uniform spray patterns, and optional pressure-boost modes. The result: better rinse performance with lower water use.

High-accuracy molds (tight tolerances, multi-shot and LSR overmolding) produce perfectly fitted parts and integrated soft-touch grips and seals — eliminating secondary assembly points that cause leaks or misalignment.

We equip shower faces with silicone self-cleaning jets, choose corrosion-resistant materials (SS304, brass) and apply robust finishes so performance stays stable in hard-water environments and high-use installations.

We engineer nozzles and internal flow channels using empirical testing to deliver consistent pressure, uniform spray patterns, and optional pressure-boost modes. The result: better rinse performance with lower water use.

Most handheld shower heads are designed to comply with international connection standards, typically G1/2″ threads, ensuring compatibility with major global markets. For custom projects, thread types, hose interfaces, and regional compliance requirements can be engineered to match local standards.

Handheld shower heads are typically produced using ABS, engineering plastics, stainless steel, brass, and silicone components. Material selection is based on durability, weight, corrosion resistance, and target market positioning. All materials can be verified with material test reports upon request.

Yes. Flow rate, spray function combinations, nozzle design, and internal water channels can be customized through mold design and insert configuration. This allows brands to meet water-saving regulations while maintaining spray comfort and performance.

Consistent spray performance is achieved through precision mold design, controlled injection molding parameters, and calibrated nozzle dimensions. Each production batch undergoes functional spray testing to verify flow uniformity and pressure stability.

Handheld shower heads can be engineered to meet regional water-efficiency standards such as flow rate limits and pressure requirements. Internal flow restrictors and optimized spray geometry are commonly integrated to balance comfort and compliance.

Quality control includes dimensional inspection, visual checks, leak testing, spray performance testing, and durability evaluation. For large-volume programs, in-process inspections and final audits ensure stable quality across mass production.

Durability depends on material choice, internal structure design, and surface finishing. Properly engineered handheld shower heads offer excellent resistance to scale buildup, thermal cycling, and daily mechanical stress in residential and commercial environments.

Yes. Common finishes include polished chrome, chrome plating, PVD coatings, and spray finishes. Finishing processes are controlled to ensure adhesion, abrasion resistance, and consistent appearance across production runs.

Leak prevention is addressed through precision sealing design, silicone gasket selection, and pressure testing. Each assembled handheld shower head is tested to confirm sealing integrity under operating conditions.

Key considerations include manufacturing capability, mold development expertise, material traceability, quality certifications, testing standards, production capacity, and the supplier’s ability to support long-term, stable supply.