OEM/ODM manufacturer delivering high-quality Sink faucets with full customization in materials, design, finishes, and packaging.

JEKARE is a trusted OEM manufacturer in the sanitary ware industry, offering one-stop design and bulk production of custom sink faucets for global brands.

We provide full customization for sink faucets, including configuration (single-hole, widespread, wall-mounted), valve technology, materials, finishes, design, and branding for high-quality, market-ready products.

All categories

Baths

Bidets

Washbasins

Faucets

Toilets

Uncategorized

Plumbing

1Pair

2Pair

3Pair

A sink faucet controls water flow, temperature, and direction for washing, rinsing, and food preparation. Modern faucets feature ceramic cartridges, aerators, spray functions, and durable finishes. Custom sink faucets can be designed for specific sink layouts, deck- or wall-mount installations, spout heights, spray styles, and branding, providing precise, durable, and visually appealing solutions for residential, commercial, and OEM projects.

There are several types and configurations of sink faucets. Understanding these types helps in selecting the right faucet for installation, replacement, or OEM projects.

Single-handle sink faucets control both water flow and temperature with one lever. They are widely used for modern kitchen and bathroom sinks due to their simplicity, space efficiency, and smooth operation.

Dual-handle sink faucets have separate controls for hot and cold water, allowing precise manual adjustment. This classic design is popular in traditional kitchens and bathrooms.

Wall-mount sink faucets are installed directly into the wall rather than the sink deck. They save counter space and are ideal for custom sink installations or commercial projects.

Deck-mount sink faucets are mounted on the sink or countertop. They are the most common type and can accommodate one-hole, three-hole, or widespread mounting configurations.

Pull-out and pull-down sink faucets feature extendable spouts for flexible cleaning and filling tasks. They are widely used in modern kitchens and can be custom engineered for spray patterns, reach, and ergonomics.

Designed for restaurants, labs, or heavy-use settings, these faucets feature durable materials, high-flow valves, and reinforced connections to handle frequent use and meet industrial standards.

All sink faucet types can be custom manufactured to meet specific installation requirements, spout styles, finishes, and OEM specifications

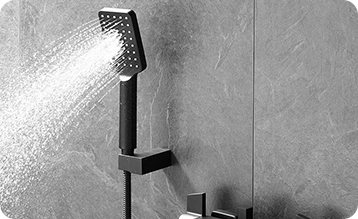

Precision-engineered cartridges and valves ensure stable water pressure and temperature. Even under fluctuating supply conditions, our shower faucets maintain a smooth, uninterrupted flow, enhancing the user experience.

We use low-lead brass and stainless steel for all critical components. These materials resist corrosion, scaling, and wear, ensuring long-lasting performance in both residential and commercial applications.

Our shower faucets are produced using CNC machining, high-precision die casting, and automated assembly. Each unit undergoes thorough dimensional, pressure, and leak testing to meet stringent quality standards.

We provide custom shower faucet solutions with tailored spout designs, handle configurations, finishes, and branding options. This allows clients to meet unique installation requirements and differentiate their products in the market..

Yes, most sink faucets are designed with industry-standard dimensions for deck or wall-mount installations. Custom sizes can also be manufactured to meet unique installation requirements.

Our sink faucets are engineered with high-capacity cartridges and valves to maintain stable flow and temperature even under high-pressure conditions, ensuring consistent performance for heavy-use settings.

We use corrosion-resistant materials such as low-lead brass and engineering-grade stainless steel. Each component is precision-machined or injection molded and undergoes rigorous pressure, leak, and wear testing.

Yes. Our manufacturing process supports custom spout designs, handle types, finishes, and branding options, allowing full OEM flexibility for commercial, hospitality, or residential projects.

Measure the deck thickness, hole spacing, and spout reach. Consider flow rate, handle style, and whether a single-hole or widespread configuration is required. OEM clients can request custom adaptations to meet specific project needs.

Routine inspection is recommended for cartridges, valves, and seals. Cleaning mineral buildup and checking for leaks can extend product life. For commercial installations, periodic maintenance schedules are recommended.

Indicators include uneven water flow, leaking around handles or spout, corrosion or scaling on internal components, or difficulty adjusting temperature.

Absolutely. Our sink faucets are designed for both high-end residential use and demanding commercial environments, with scalable solutions for varying flow rates and durability requirements.