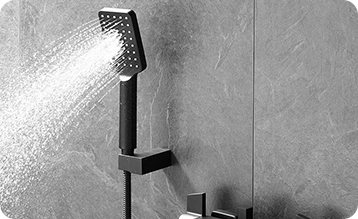

Professional shower hose manufacturer in China. We produce custom, kink-resistant stainless steel braided hoses for OEM bathroom brands.

A custom shower hose connects handheld shower heads to water outlets, providing flexible, leak-proof performance. JEKARE manufactures durable hoses with stainless steel braiding, high-quality fittings, and kink-resistant inner tubes.

JEKARE offers shower hoses in standard and custom lengths, designed for easy installation, low maintenance, and reliable performance, enhancing any shower system for both residential and commercial applications.

All categories

Baths

Bidets

Washbasins

Faucets

Toilets

Uncategorized

Plumbing

1Pair

2Pair

3Pair

A shower hose is a flexible conduit connecting a hand shower to the water supply, enabling adjustable spray while maintaining consistent flow. Made from stainless steel braid, reinforced PVC, or rubber, quality hoses resist kinks, corrosion, and mineral buildup. Custom hoses can be tailored in length, fittings, materials, and finishes to meet OEM or project specifications, ensuring durable, high-performance solutions for residential, commercial, and hospitality applications.

There are several designs and construction styles of shower hoses. When choosing the correct replacement or specifying hoses for a project, understanding these types helps you quickly identify the features you need for compatibility, durability, and installation.

Most modern replacement hoses come with finished end fittings that match common shower connections. The fittings are crimped or swaged to the hose and finished to match the shower hardware, making installation fast and reliable.

Male-fitting hoses have external threads on the hose end that screw into a female inlet on the hand shower or wall outlet. This configuration is common where the fixture or bracket accepts an externally threaded connection.

Female-fitting hoses have internal threads at the end fitting and screw onto a male-threaded spout or hand shower. The outside of the fitting is smooth and the hose slips into place and tightens onto the fixture’s external thread.

Some hoses are supplied without finished ends so they can be cut and terminated on-site or by the OEM with custom fittings. These save on inventory SKUs but require crimp/swage tooling and correct sealing during assembly to ensure leak-free joints.

Hidden-connection hoses are designed to mate with fittings recessed behind trim or inside a wall plate so the hose-to-fixture junction is not visible. These hoses often use short male or female adapters that seat inside the trim for a clean, low-profile look — ideal for minimalist or concealed installations.

We build hoses from engineered cores (PTFE or reinforced rubber) with stainless-steel braid or braided polymer jackets for max durability. Finishes such as electroplating, PVD, or passivation are applied to metal fittings so hoses resist corrosion, discoloration, and mineral buildup in humid bathroom environments.

All fittings are swaged/crimped or cold-formed to the hose with precision tooling and fitted with engineered O-rings/seals (EPDM/NBR). This factory termination process eliminates common field-assembly failure modes and delivers reliable, repeatable, leak-free joints out of the box.

Internal liners and reinforced braid are specified and tested to maintain consistent flow and pressure while preventing kinks or collapses. We design nozzle and connector geometry to minimize pressure loss and ensure smooth, splash-free delivery across typical household and commercial supply pressures.

As a factory we offer custom lengths, end fittings, thread standards, and branded finishes to meet project specs. Every run undergoes dimensional inspection, pressure/burst testing, cycle fatigue testing, and salt-spray/corrosion checks. Batch traceability and tailored packaging complete the B2B supply chain readiness.

Professional shower hoses are typically produced using a multi-layer structure, such as an inner tube made from EPDM rubber, PVC, or PTFE, combined with an outer stainless steel braid or reinforced polymer sleeve. Material selection depends on pressure requirements, temperature resistance, flexibility, and target market standards.

Leak prevention is achieved through precision crimping or swaging of fittings, controlled torque assembly, and the use of engineered sealing components such as EPDM or NBR O-rings. Each hose assembly undergoes pressure and air-leak testing during production to ensure consistent sealing performance.

Metal fittings are finished using electroplating, PVD coating, or passivation processes to enhance corrosion resistance, surface hardness, and aesthetic consistency. Salt spray testing is commonly used to validate coating durability for humid bathroom environments.

Industrial-grade shower hoses are designed to withstand working pressures typically between 0.5–1.6 MPa and temperatures up to 90–120°C, depending on inner tube material. Burst pressure testing is performed to ensure a safety margin well above rated conditions.

Yes. As a manufacturing factory, we support custom hose lengths, thread standards (G1/2, NPT, BSP), connector designs, surface finishes, logos, and packaging. OEM projects can also specify material grades and performance benchmarks.

Anti-kink performance is achieved through optimized braid density, reinforced inner liners, and controlled flexibility of the outer jacket. Some designs also integrate swivel connectors to reduce torsional stress during use.

Standard QC procedures include dimensional inspection, pressure testing, burst testing, fatigue cycle testing, pull-out force testing, and corrosion resistance evaluation. Batch traceability is maintained to ensure consistency across large-volume orders.

Professional factories manufacture shower hoses in compliance with global standards such as ISO, EN, WRAS, and NSF requirements, depending on the target market. Compliance documentation can be provided for importers and brand owners.

Under normal operating conditions, a high-quality shower hose has a service life of 5–10 years. Longevity depends on material selection, water quality, pressure stability, and surface finish durability.

Manufacturers offer flexible packaging solutions including bulk cartons, individual polybags, branded retail boxes, barcode labeling, and palletized export packaging to meet distributor and retail channel requirements.