Top supplier and manufacturer of custom shower head holders in China. We specialize in OEM production of durable, adjustable brackets for global brands.

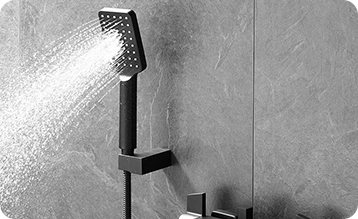

A shower head holder is a mounting accessory for handheld showers, enabling secure positioning and adjustable spray direction. JEKARE manufactures durable holders with smooth adjustment and corrosion-resistant finishes.

We offer standard and custom shower head holders, including fixed and sliding brackets. Customizable finishes, mounting styles, dimensions, and logo branding ensure durable, easy-to-install solutions for any bathroom.

All categories

Baths

Bidets

Washbasins

Faucets

Toilets

Uncategorized

Plumbing

1Pair

2Pair

3Pair

A shower head holder is a bathroom fixture that securely supports and positions a shower head, allowing adjustable height and angle for a comfortable, hands-free shower. Custom holders can be tailored for finishes, dimensions, and compatibility with various shower head types, meeting specific installation and design requirements. Engineered for durability and ease of use, they are ideal for both residential and commercial bathroom applications.

There are several types and designs of shower head holders. When selecting the right holder for a fixed or hand-held shower system, understanding these types helps you quickly identify the structure, mounting method, and functional features required for your application.

Wall-mounted holders are the most common type, designed to be fixed directly onto the shower wall. They provide stable support for hand showers or fixed heads and are available in adjustable or fixed-angle designs. These holders are typically matched to the shower set’s finish for a cohesive appearance.

Adjustable holders feature a swivel or ball-joint mechanism that allows the shower head angle to be easily changed. This design improves user comfort and accessibility and is widely used in residential and hospitality applications where flexibility is required.

Fixed angle holders are designed with a preset spray direction and no moving parts. Their simple structure offers enhanced durability and is ideal for cost-sensitive projects or commercial installations that prioritize long-term reliability.

Slide bar holders are mounted on a vertical rail, allowing the shower head height to be adjusted smoothly. This type is commonly used in family bathrooms, hotels, and accessible showers, offering ergonomic benefits for users of different heights.

Integrated holders are built directly into the shower arm or bracket assembly, creating a clean and minimal appearance. This design reduces installation components and is well-suited for modern or concealed shower systems.

Concealed mount holders hide mounting hardware behind the wall or decorative cover, delivering a sleek, premium look. They are often specified in high-end bathroom designs where aesthetics and clean lines are a priority.

We design holders with precision-machined brackets and multi-point fastening so the holder stays rigid under frequent use. CNC-machined metal cores or die-cast housings combined with torque-controlled screws eliminate wobble and loosening over time — critical for commercial and high-use installations.

Our gliders and swivel joints use CNC or high-precision injection-molded parts with low-friction bushings (PTFE/nylon) and indexed locking detents. That engineering produces effortless height/angle adjustment and positive lock performance even after hundreds of thousands of cycles.

We apply industrial finishes (PVD, electroplating, or powder coat) and perform passivation or salt-spray testing to ensure long-term corrosion resistance. Smooth, non-porous surface treatments reduce limescale buildup and simplify cleaning — important for longevity and sanitary performance in bathrooms.

As a manufacturer we offer custom lengths, bracket spacing, materials (stainless steel, brass, reinforced polymers), and mounting options (exposed, concealed, slide bar). Every production run includes dimensional checks, load/cycle testing, and final visual/functional inspection with batch traceability so you receive consistent, spec-compliant units for your projects.

Yes, shower head holders are typically manufactured in a range of standard sizes to fit most shower heads. However, customization options are available to meet specific requirements, especially for commercial applications or unique designs.

Most shower head holders are compatible with a wide variety of shower heads, but it is important to ensure the holder’s design matches the shower head’s connection size and type. For example, adjustable holders accommodate various shower head diameters, while fixed holders may require specific thread patterns.

High-quality materials such as stainless steel, brass, or durable polymers ensure long-term strength and corrosion resistance. Surface treatments like PVD coating or electroplating are commonly used to enhance durability, resist rust, and maintain the finish in humid environments.

Shower head holders can be finished with various coatings such as chrome plating, matte black, brushed nickel, or polished brass. The choice of finish not only impacts the aesthetic appearance but also the resistance to scratches, water spots, and tarnishing.

Yes, custom designs and finishes are available. We can tailor shower head holders to meet specific client requirements, including custom lengths, mounting styles (wall-mounted, slide bars), and materials. Customization is particularly useful for high-end hotel projects or branded designs.

For durability and secure installation, our holders use heavy-duty mounting brackets and adjustable locking mechanisms. We recommend using high-strength anchors or wall plates for installations on various surface types to ensure the holder can support the weight of the shower head under normal use.

Our shower head holders undergo stress tests, including load-bearing tests and cycle testing for functionality. We also perform corrosion resistance testing, especially for holders made of metal, to ensure they withstand moisture and high-humidity environments without degradation.

Shower head holders are designed for long-term use. However, it’s recommended to inspect and clean them regularly, especially around the locking mechanism or adjustable joints, to prevent buildup of soap scum or lime deposits. Replacement may be necessary if the holder becomes loose, shows signs of corrosion, or if the adjustment mechanism becomes worn.

Yes, installation instructions are provided for each shower head holder model. It’s essential to follow the specified mounting guidelines, including torque settings for screws and the correct depth for wall anchors. Professional installation is recommended for complex designs or commercial applications.

Yes, we offer bulk ordering for commercial projects. Whether it’s for hotels, fitness centers, or large-scale renovations, we provide custom options, competitive pricing, and fast lead times to meet your specific project needs.