Leading manufacturer & supplier of custom rain shower heads (rainfall/overhead showers) in China.

Rain shower heads—also called rainfall, overhead, or ceiling-mounted showers—are a popular choice for modern bathrooms. JEKARE is a trusted OEM/ODM manufacturer offering factory-direct design and bulk production for global sanitary-ware brands.

We offer full OEM/ODM customization for rain shower heads, covering materials (ABS, stainless steel, brass), sizes, shapes, finishes, spray functions, logo branding, packaging, and performance specifications.

All categories

Baths

Bidets

Washbasins

Faucets

Toilets

Uncategorized

Plumbing

1Pair

2Pair

3Pair

A rain shower head is a large-format overhead shower fixture designed to deliver a wide, gentle, rainfall-like water pattern. Installed on the ceiling or a raised shower arm, it distributes water evenly across a broad surface area, creating a soft, immersive shower experience. Modern rain shower heads are engineered to optimize flow distribution and pressure balance, helping reduce splashing while maintaining consistent coverage. Many designs also support water-saving flow rates and advanced spray technologies, making rain shower heads a preferred choice for premium residential, hospitality, and commercial bathroom applications.

Installed flush to the ceiling for true overhead rainfall, these large-format heads deliver full-coverage, spa-like spray. Popular in high-end bathrooms, they’re typically made from SS304, brass, or high-grade ABS and require in-ceiling plumbing.

Mounted on the wall or on an arm extension, wall-mounted rain heads offer easier retrofit installation while still providing wide, gentle coverage. Available in square, round, and oval profiles to match different design aesthetics.

Extra-large diameters (12–24″+) create immersive coverage and even spray distribution. Ideal for luxury installations—these units prioritize uniform flow and often incorporate anti-clog nozzle arrays for low-maintenance performance.

Featuring a linear slot or elongated outlet, waterfall rain heads produce a broad, sheet-like flow that mimics a natural waterfall. They deliver a different sensory experience and are frequently used in contemporary or minimalist designs.

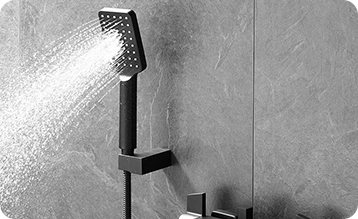

Combine a rain surface with integrated handhelds, body jets, or adjustable spray zones—offering flexibility for varied water pressures and user preferences. These hybrid units are engineered for bundled systems and turnkey installation.

Designed for shallow ceiling cavities or minimalist looks, low-profile rain heads provide the rainfall effect with a reduced mounting depth. They’re well-suited to remodels with limited ceiling space.

Incorporate LED lighting, digital flow control, or touchless activation for modern, tech-enhanced bathrooms. These units require electrical integration and are targeted at premium and hospitality markets.

We design rain spray patterns using validated flow-profiling and precision mold tooling so each shower head delivers uniform coverage and consistent droplet size. Optimized nozzle geometry improves perceived pressure while meeting target flow-rates and regulatory limits.

Soft LSR or silicone nozzle arrays and engineered outlet channels reduce scale buildup and enable easy self-cleaning. This minimizes service calls and warranty claims for hospitality and residential installations.

Body materials (SS304/solid brass) and advanced surface finishes (PVD, chrome, brushed) provide long-term corrosion resistance and stable appearance in wet environments — keeping products reliable and brand-worthy over time.

From high-accuracy molds and CNC components to controlled molding, plating, and assembly, we enforce in-process controls and full performance testing (flow pattern, pressure, salt spray, life-cycle). That factory discipline yields repeatable quality and predictable scale production for custom rain shower head programs.

Most high-quality rain shower heads are made from stainless steel (SS304), brass, ABS plastic, or a combination with LSR components for flexible spray nozzles. Material choice affects durability, corrosion resistance, and surface finishing options.

Yes, OEM customization includes size, spray pattern, nozzle design, surface finish (polished chrome, brushed nickel, PVD coatings), and branding. Customization ensures compatibility with specific plumbing systems and market requirements.

Our engineering team conducts flow simulation, spray performance testing, and pressure validation during prototyping and production to maintain uniform water distribution and desired flow rates across all units.

Yes, our rain shower heads are designed to fit standard 1/2-inch or 3/4-inch plumbing fittings, but we can provide custom connector types and thread options for specific markets or client specifications.

Precision mold tooling, LSR nozzle overmolding, and high-tolerance machining ensure no leakage and consistent performance. Each unit undergoes rigorous leak and spray testing before shipment.

We provide polishing, chrome plating, PVD, and spray coating, ensuring aesthetic consistency, scratch resistance, and corrosion protection for commercial and residential applications.

Absolutely. Our units are compatible with standard mixer valves, thermostatic systems, and integrated shower columns. Custom adapter solutions are available for non-standard installations.

Every rain shower head undergoes multi-stage inspection: dimensional verification, pressure and leak testing, spray pattern assessment, and visual surface quality checks. ISO9001-compliant procedures ensure consistency.

Lead times depend on complexity, mold development, and volume. Typically, 4–8 weeks for new OEM designs, including prototyping and trial runs, with scalable mass production thereafter.

Yes, we offer turnkey packaging solutions, including custom branding, box design, and protective packaging suitable for retail or project shipments.